Transform Your Manufacturing with CNC Machining Precision

- PMC Power

- Sep 15, 2025

- 4 min read

In today’s competitive manufacturing landscape, precision and efficiency are more important than ever. Businesses are constantly seeking ways to improve product quality, reduce waste, and speed up production times. One of the most effective ways to achieve these goals is by integrating precision CNC solutions into your manufacturing processes. These advanced technologies offer unparalleled accuracy and repeatability, enabling manufacturers to produce complex parts with ease and consistency.

Unlocking the Power of Precision CNC Solutions

Precision CNC solutions refer to computer numerical control systems that automate machining tools with high accuracy. These systems use computer programming to control the movement of cutting tools, allowing for precise shaping, drilling, and finishing of materials. The benefits of adopting precision CNC solutions include:

Enhanced accuracy: CNC machines can achieve tolerances as tight as a few microns, ensuring parts fit perfectly.

Improved repeatability: Once programmed, CNC machines can produce identical parts repeatedly without variation.

Increased productivity: Automation reduces manual labor and speeds up production cycles.

Flexibility: CNC machines can be quickly reprogrammed to manufacture different parts, supporting small batch runs and custom orders.

Reduced waste: Precise cutting minimizes material scrap, lowering costs and environmental impact.

For example, a manufacturer producing aerospace components can rely on precision CNC solutions to meet strict industry standards. The ability to produce complex geometries with exact specifications ensures safety and performance in critical applications.

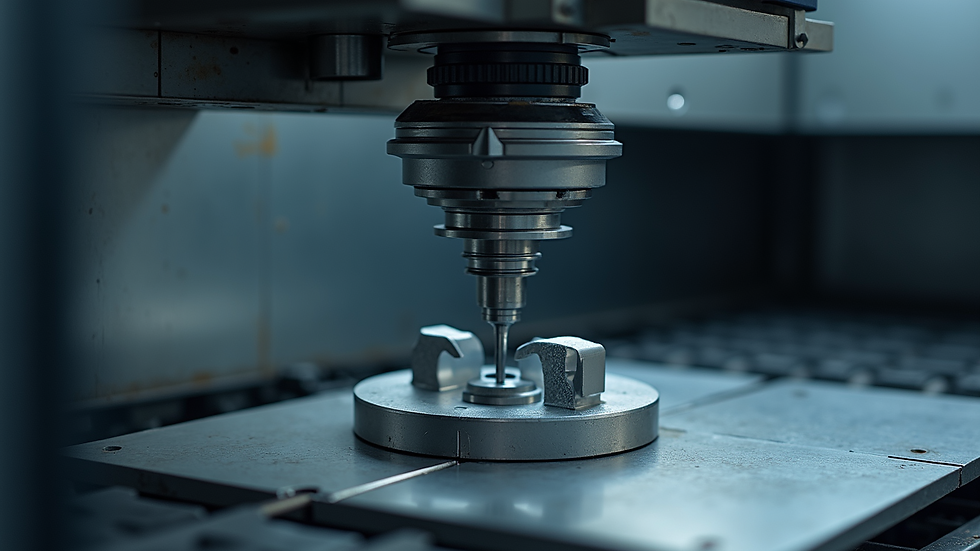

Close-up view of CNC machine cutting metal with precision

How Precision CNC Solutions Revolutionize Manufacturing

The integration of precision CNC solutions transforms traditional manufacturing in several key ways:

Streamlined Production Workflow

By automating machining tasks, CNC systems reduce the need for manual intervention. This streamlines the production workflow, allowing operators to focus on quality control and maintenance rather than repetitive tasks. For instance, a factory using CNC milling machines can run multiple shifts with minimal supervision, increasing output without compromising quality.

Consistent Quality Control

Precision CNC solutions enable manufacturers to maintain consistent quality across large production runs. The programmed instructions ensure every part is machined to the same specifications, reducing variability and defects. This consistency is crucial in industries such as automotive and medical device manufacturing, where precision is non-negotiable.

Cost Efficiency and Resource Optimization

Although the initial investment in CNC technology can be significant, the long-term savings are substantial. Precision machining reduces material waste and lowers labor costs. Additionally, faster production times mean quicker turnaround for orders, improving cash flow and customer satisfaction.

Enhanced Design Capabilities

CNC machines can handle complex designs that would be difficult or impossible to achieve manually. This opens up new possibilities for product innovation. For example, manufacturers can create intricate cooling channels in engine parts or lightweight lattice structures in aerospace components, improving performance and reducing weight.

Eye-level view of CNC machine producing complex metal part

Choosing the Right Precision CNC Solutions for Your Business

Selecting the appropriate CNC technology depends on several factors:

Material type: Different machines are optimized for metals, plastics, or composites.

Part complexity: More complex parts may require multi-axis CNC machines.

Production volume: High-volume production benefits from automated tool changers and pallet systems.

Budget: Consider both upfront costs and long-term operational expenses.

Support and training: Reliable technical support and operator training are essential for maximizing machine performance.

For example, a small manufacturer specializing in custom metal parts might invest in a 3-axis CNC milling machine for flexibility and cost-effectiveness. In contrast, a large automotive supplier may require 5-axis CNC machines with robotic automation to meet high-volume demands.

Integrating CNC Machining into Your Manufacturing Process

To fully leverage the advantages of precision CNC solutions, manufacturers should follow these actionable steps:

Assess current capabilities: Identify bottlenecks and quality issues in your existing processes.

Define goals: Set clear objectives such as reducing lead times, improving tolerances, or expanding product offerings.

Select appropriate CNC equipment: Choose machines that align with your production needs and budget.

Train staff: Invest in operator training to ensure efficient and safe machine use.

Implement quality control systems: Use inspection tools and software to monitor part accuracy.

Optimize workflows: Integrate CNC machines with other manufacturing systems for seamless operations.

By following these steps, manufacturers can ensure a smooth transition to CNC-based production and maximize return on investment.

High angle view of CNC machine operator monitoring production

Future Trends in Precision CNC Solutions

The future of manufacturing is closely tied to advancements in CNC technology. Emerging trends include:

Artificial intelligence and machine learning: These technologies will enable predictive maintenance and adaptive machining processes.

Internet of Things (IoT) integration: Connected CNC machines will provide real-time data for improved decision-making.

Additive manufacturing hybrid systems: Combining CNC machining with 3D printing will allow for even more complex and customized parts.

Sustainability focus: Energy-efficient CNC machines and eco-friendly materials will reduce environmental impact.

Staying informed about these trends will help manufacturers remain competitive and innovative in a rapidly evolving market.

Embrace Precision CNC Solutions Today

Incorporating precision CNC solutions into your manufacturing operations is a strategic move that can significantly enhance product quality, efficiency, and flexibility. Whether you are producing aerospace components, automotive parts, or custom machinery, these technologies offer the precision and reliability needed to meet demanding standards.

Explore how cnc machining can transform your manufacturing process and position your business for future success. With the right equipment, training, and workflow optimization, you can unlock new levels of productivity and innovation.

Start your journey toward precision manufacturing today and experience the difference that advanced CNC solutions can make.

Comments